|

Charlotte Stonestreet

Managing Editor |

| Home> | DRIVES & MOTORS | >Synchronous Motors | >Lower energy, maintenance & noise |

Lower energy, maintenance & noise

19 February 2016

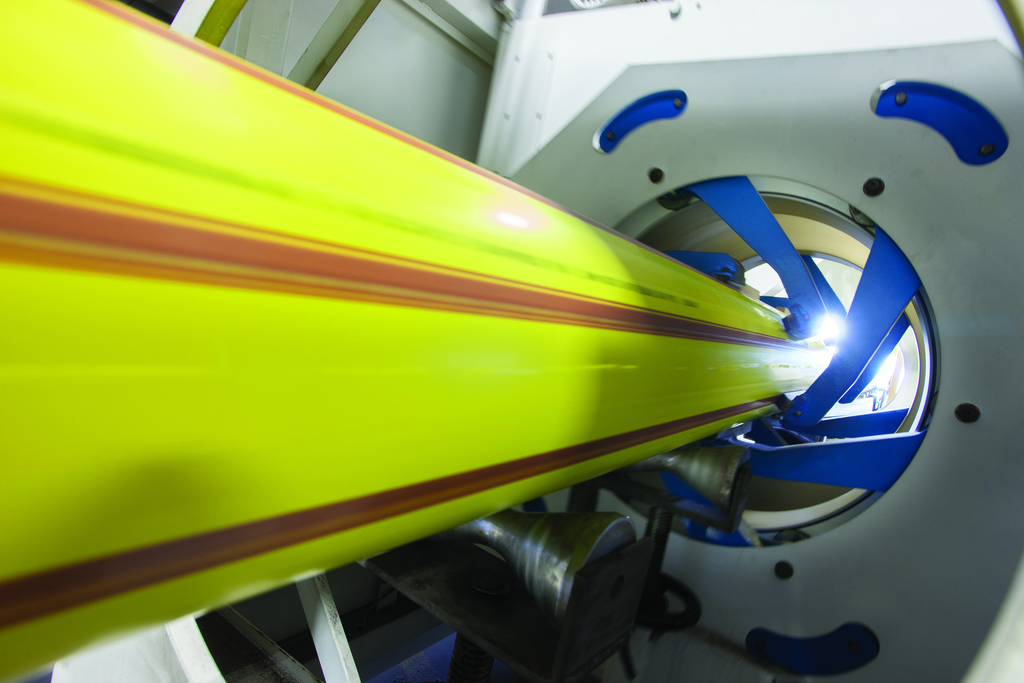

Up to 15% lower energy use, a significant reduction in motor maintenance costs and a drop in audible noise are reported following installation of an ABB synchronous reluctance motor and drive (SynRM) package on a twin extruder application at Radius Systems in Derbyshire, which houses 14 extrusion lines.

The SynRM selected for the application is a 200kW, 1500rpm, IE4 solution and together with the ABB industrial drive, ACS880, it offers a much higher efficiency than standard AC induction motors and drives. It is also a far quieter package than the existing DC motor.

SynRM can be up to two frame sizes smaller than a conventional induction motor which is a benefit in the direct replacements of DC motors.

- ABB wins at Pump Industry Awards

- High performance motor control

- PLC KEY TO MISSING LABELS DETECTION

- Touchscreen data recorder

- ABB’s YuMi comes to Smartech Selfridges

- Factory of the future

- New possibilities for industrial measurement

- Turnkey Project

- ABB launches Drives Solutions Team

- Advanced services

- High Speed, Low Vibration

- HIGHER TORQUE

- Fast Payback In High Power Applications

- Synchronous PM Motors - IE4

- Production line upgrade

- Natural ventilation permits wider use of torque motors

- Permanent-magnet motor surpasses IE4 standard

- IE5 efficiency without rare earth magnets

- Interroll raises profile

- Reliability issues solved