|

Charlotte Stonestreet

Managing Editor |

| Home> | DRIVES & MOTORS | >Servo Motors & Drives | >Energy-saving modular drive |

Editor's Pick

Energy-saving modular drive

16 December 2016

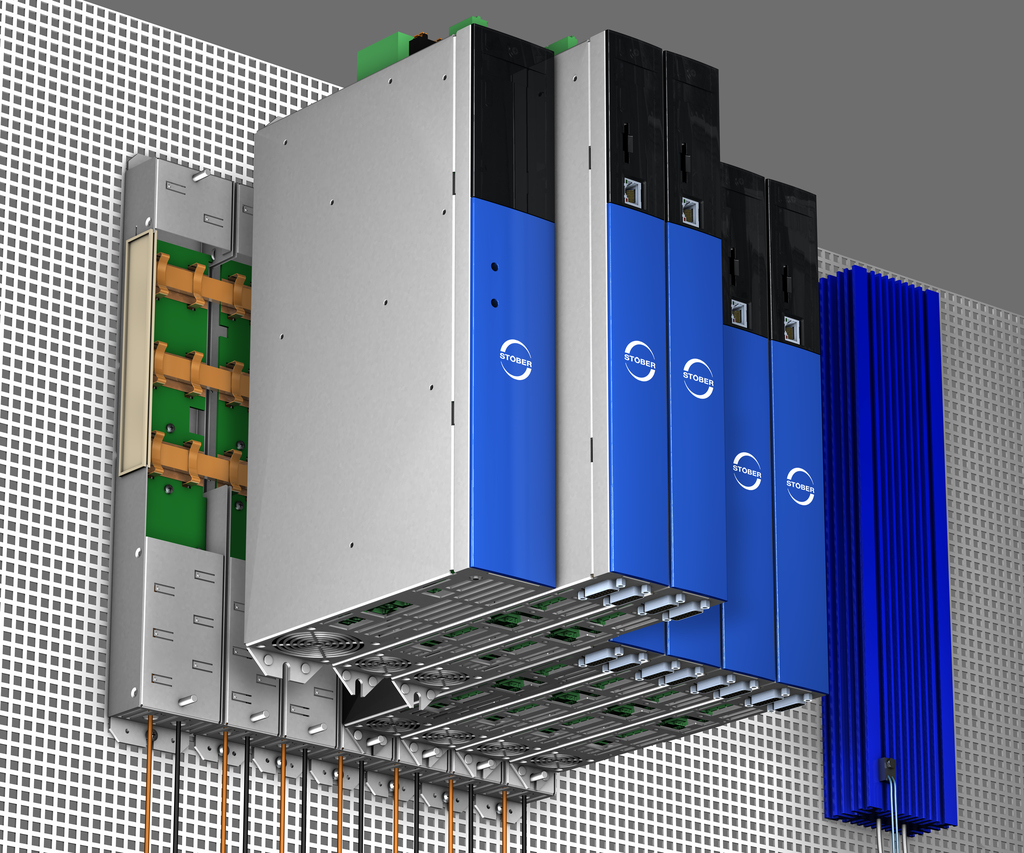

New from Stober, the modular SI6 Drive System with single centralised power supply is reported to be the smallest multi axis servo drive available.

The SI6 is a modular and scalable Rack System for machine builders with multiple axes that, says Stober, will save costs in in hardware, energy use and installation. The double axis module, which provides 2 x 5 amps, is just 45mm wide yet delivers a position, speed and current cycle time of only 62,5 µs.

Available in five sizes and with two power options, the new SI6 saves both space and energy, and is so compact that a 20 axis system occupies a space of just 495mm. The integration of Stober’s patented Quick DC-Link system using one bus voltage means that energy generated from one drive can be harnessed by the other modules, resulting in more power for less investment.

Martin Preece, sales director of Stober Drives UK, explains: “Whilst the compact nature of the SI6 is a big benefit, the omission of unnecessary power supplies is even more decisive. The modular nature of the SI6 means that the entire series of drive controllers can be connected by a central supply module, which negates the need for fuses and cabling on individual units. This means that power from one module is accelerated to the next module and so on.

“Consequently, Stober’s new SI6 gives engineers a significant reduction in both space and costs. For example, a width of 180mm is sufficient for a drive controller and supply module system with six axes. Additionally, double axis modules can also be combined with stand-alone units from the Stober SD6 series, so regardless of whether you incorporate 4, 16 or 97 axes, capacity is precisely dimensioned.”

In terms of acceleration, the Stober SI6 drive controller has plenty to offer. In combination with the Stober synchronous EZ401 servo motor it accelerates from 0 to 3000 rpm in 10 ms and this interaction of drive controller, servo motor and encoder enables machine operators to make precise changes in speed to suit manufacturing requirements.

The SI6 is also very quick and easy to fit, simply clicking into place with minimum wiring required.

With safety in mind, Stober has built in a STO (”Safe Torque Off”) function that can be controlled via terminals as well as via Fail Safe over EtherCAT (FSoE). Also, the SI6 is categorized in the highest Performance Level PLe (cat. 4), SIL3.

For control simplicity, Ethernet-based fieldbus systems EtherCAT and PROFINET are available as standard and through the device profile CiA 402 the SI6 can be seamlessly integrated into Controller-Based and Drive-Based Solutions.

The easy interaction of its components is paramount at STOBER, so naturally there are also no ‘language barriers’ with the SI6, and thanks to Ethernet over EtherCAT-protocol (EoE), Ethernet data is transported in the EtherCAT system.

- Largest in class servo planetary gears

- Right-angle servo gearbox

- RACK-AND-PINION REDESIGN CUTS GEAR SIZES

- Precision racks have twice the holes

- High power supply for multi-axis drive systems

- Online drive specification configurator

- Long service life components

- Sizing to the load

- Widening the scope of rack-and-pinion

- Digital shift control