|

Charlotte Stonestreet

Managing Editor |

| Home> | POWER TRANSMISSION | >Bearings | >SKF launches software centre for condition monitoring |

| Home> | AUTOMATION | >Condition Monitoring | >SKF launches software centre for condition monitoring |

Editor's Pick

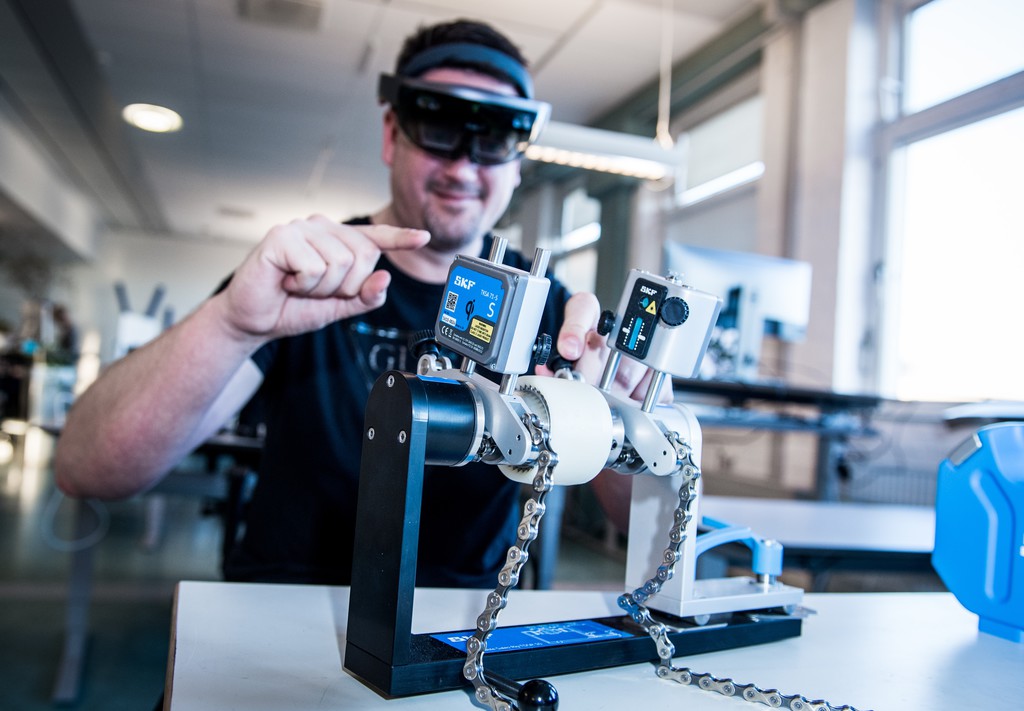

SKF launches software centre for condition monitoring

30 June 2017

The market for products and services related to monitoring the condition of machinery within industry is growing.

For example, it is possible to electronically read a lot of information on the condition of a machine and its operational deviations, based on the rotation pattern of the bearing at work. The aim as far as possible is to avoid emergency stoppages, which are associated with major costs from production losses.

Now, SKF is making a major investment by opening a software centre in Sweden in order to develop next generation technology for condition monitoring. “We are currently recruiting and the unit will include around 50 developers, most of whom will be based in Gothenburg,” says Fredrik Magnusson, who is in charge of the new software development unit at SKF. “It is an important strategic focus for SKF to help its customers with their rotating equipment. We can see the potential in the market for services and mobile solutions for effective maintenance, as many companies are moving from a reactive to a more proactive maintenance strategy.

The change follows SKF Group’s decision to concentrate all competences for the development of hardware and software for Europe in Gothenburg and Luleå in Sweden, and Aberdeen and Livingston in Scotland. The largest unit will be located in Gothenburg and will be responsible for the software development of next generation technology. The unit in Luleå has been developing and manufacturing fixed online systems since the late 1980s and will be strengthened with five additional team members.

“From a global perspective, locating the centre in Gothenburg provides a strategic benefit. We have advanced a great deal in western Sweden in terms of developing the Internet of Things, digitalisation and smart solutions for industry,” says Fredrik.

- SKF power transmission products help simplify the supply chain

- White etching cracks: causes & mitigation

- SKF Commences Civil Action Over Counterfeit Bearings

- Bearing with food safety features

- Affordable machine health monitoring

- Bearing rating life model

- Magnetic system

- Keeping the beer flowing

- Bearing analysis streamlined

- More motor efficiency