|

Charlotte Stonestreet

Managing Editor |

Get the measure of sensor solutions

27 August 2025

If you want to measure any aspect of an industrial process, chances are there's a suitable sensor solution. Ian Manning takes a look at some of the most ubiqitous applications

WHEN IT comes looking at what properties can be measured, there are certainly more more properties than can be covered in one article! So, this copy will concentrate on the most common properties: Temperature, pressure, level, flow, humidity and vibration.

Temperature

Temperature can be measured with either contact probes or remotely with infrared detection. Contact probes typically use either thermocouples or resistance. They have a wide temperature range -200°C to +1800° and have high accuracy and stability, but require contact with the medium being measured.

Infrared sensors (Pyrometers) work by detecting infrared radiation emitted by an object. While typical sensors have a temperature range of -20°C to +300°C, more specialised sensors can measure up to 3000°C. They have a fast response (75mS) and an accuracy of 1°C or 2°C. They are non-contact, can measure the temperature from up to 1 metre away, and can also be used to detect the presence or position of moving hot objects, such as food exiting an oven, or hot glue detection on a packing box.

Pressure

Most industrial pressure sensors use a strain gauge, which has good accuracy and can have a wide variety of housing materials for different environments. As they can be affected by temperature, many have built-in temperature compensation. In order to achieve the best accuracy, pressure sensors are typically designed for a narrow measuring range, however wide range sensors are available. Choosing the sensor to cover just the measuring range required will usually produce the best results. Measuring ranges can be as small as 0.03bar or up to 1000bar.

Level Measuring the level of solids or liquids in a tank, silo or other container can be divided into Point level and Continuous categories, which subdivide into Contact and Non-contact.

Point level, detecting when the material has reached a certain point and continuous level where the level of the material is measured over a range, and the sensor output is either analogue or digital data.

Point level is often used for either pump in/out control or as a call for manual fill. When the low level is detected the pump is turned on to fill the tank, or an alarm is given for the tank to be manually filled by the operator. When the level reaches the high level the pump switches off or the operator is warned that the tank is at the desired level.

Typical sensors for point level are:

- Optical, either looking through a sight glass or down on to the material surface (non-contact)

- Float switches, which sit on a liquid surface and activates a switch. (Contact) Capacitive, which detect change between the (non-metallic) tank wall and liquid (non-contact)

Continuous level measurement typically uses:

- Probes: These work on a principal of conduction either electrical or microwave. The probe or probes extend into the liquid and the liquid conducts the energy to a second probe or metal tank wall. The amount of conduction increases with the length of probe covered by the liquid. They can be used in pressure tanks but need a liquid with a dielectric constant greater 1.8 (contact)

- Ultrasonic: These work by bouncing a sound wave off of the surface of the medium and measuring the time of flight. They can have either an analogue output or digital data. They require a medium that doesn’t absorb sound (non-contact)

- Radar: These work in a similar way to ultrasonic but use pulses in the GHz frequency band. They are accurate and not affected by surface foam, temperature or pressure. Different frequency versions are available to detect different materials. They are often a good substitute for ultrasonic and also have analogue and digital data outputs (non-contact)

- Optical: Laser point and laser area scanning. Optical sensors and laser point sensors measure the distance to a point or small area on the target material. They have switched, analogue, and digital data outputs. (Non-contact) Area scanning laser sensors measure the distance to tens of thousands of points in an area and can output the peak height and percentage fill of a container. They are a good choice for containers with an irregular fill level, or containers with randomly sized items.

Flow

Flow sensors are typically contact type sensors.

- Mechanical Moving: The fluid either turns a rotor and the rotational speed is used to calculate the flow, or the fluid moves a piston in an internal chamber and the amount of movement is used to calculate the flow

- Differential Pressure: A flow restriction is used which creates a pressure drop and the pressure is measured either side of the restriction. The flow rate is calculated in relation to the size of the pressure difference. Not suitable for low flow rates.

- Calorimetric (heat transfer): The flow of the medium over the probe transfers heat from one side to the other. The amount of heat transferred is proportional to the flow rate. The temperature of the medium is also measured.

There are many other types of flow sensors such as electromagnetic for conductive materials, ultrasonic using the doppler effect, and vortex detection.

Humidity

Humidity sensors have to have an open-face construction in order for the moisture in the environment to interact with the sensor.

- Capacitive: a hydroscopic dielectric material between two electrodes changes the capacitance as the humidity changes.

- Resistive: a polymer material changes its electrical resistance with moisture absorption. Typically less accurate than capacitive.

Temperature and humidity sensors are often combined.

Vibration

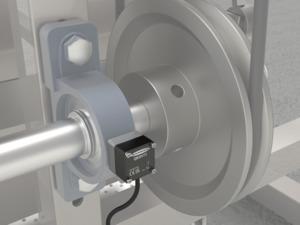

The most common type of vibration sensors use accelerometers in one, two or three planes. They are commonly used for condition monitoring for predictive maintenance. A single plane vibration sensor will detect the vibration in one direction of motion. This may be sufficient if the direction of the expected vibration is known. A worn bearing in a motor will typically produce vibration perpendicular to the rotating shaft. However a worn thrust bearing creates axial vibration (in line with the shaft) and a two or three axis sensor will be better to detect this.

Turck and Banner Engineering combined have the widest range of sensors in the world. Turck Banner Ltd, their UK daughter company, offers expertise in the fields of sensing and industrial/process automation. The company offers solutions to fit everything from a simple cost effective, stand-alone sensor and indicator, through to a fully networked turnkey solution.

Ian Manning is marketing manager at Turck Banner

- No related articles listed