|

Charlotte Stonestreet

Managing Editor |

| Home> | POWER TRANSMISSION | >Bearings | >Beyond face value |

Editor's Pick

Beyond face value

28 April 2023

Next time there is a need to specify bearings, it is worth considering an added-value solution, not simply a quick fix for immediate gain asserts Charlie Kortens

ALL COMPANIES, whatever the industry, will have encountered the inconvenience and cost of a bearing failure. A machine or possibly even a whole production line comes to a halt, the clock is ticking and the maintenance team is under pressure. There is no time to weigh up the options; time is money, after all. A few months, weeks or even days later, the same bearing failure occurs. Back to square one.

While situations like these are clearly unsustainable, they are simple to rectify. With a little planning and foresight it is possible to ensure a more reliable and, over the long term, more cost-effective bearing solution. Bearing selection should be about delivering comprehensive, sustainable improvements, ensuring dependable performance without unplanned stoppages. Such an outcome enhances productivity and profitability, while reducing total cost of ownership (TCO).

High-performance standard

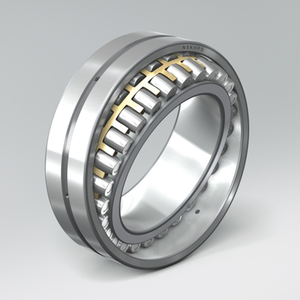

More and more companies are beginning to realise that bearings are not simple commodity items, but components with the potential to add real value. A case in point are bearings made to the NSK High-Performance Standard (NSKHPS). Currently more than 30,000 NSK bearings in all common configurations are available in the NSKHPS design.

Central features of this standard include the use of a special, high-purity bearing steel, and an innovative surface treatment for the running surfaces of the rings and rolling elements. NSK produces this surface using grinding and polishing processes (superfinishing), creating the conditions necessary for the grease to deliver its optimal lubricating effect.

The combination of these features results in significantly higher dynamic load ratings and, subsequently, longer service life. In fact, NSKHPS bearings deliver service life up to twice that of the company’s industry-standard bearings. A longer service life means fewer replacements, less production downtime and lower TCO. The value is clear to see.

Heavy-duty demands

Unsurprisingly, many OEMs and end users opt for NSKHPS series bearings when there is a need for extended service life in arduous operating conditions, like the heavy and high impact loads encountered in steelmaking, mining and construction applications, or the extreme speeds and high heat present in papermaking, for example. NSKHPS bearings maintain dimensional stability in challenging environments of this nature.

These bearings are also performance enhancers. In the case of spherical roller bearings, the NSKHPS series offers 20% higher limiting speed and 25% higher dynamic load rating, enabling OEMs to downsize machines without any loss of capacity.

Further advantages include the ability to operate effectively in temperatures up to 200°C, optimal raceway design and surface finish for durability and wear resistance, higher permissible misalignment, and availability with a strengthened steel cage or heavy-duty brass cage. Low running noise and reduced heat generation are additional benefits thanks to improved lubricant flow.

Added value in action

There are countless examples of how NSKHPS series have delivered notable added value across industry. For instance, when NSK engineers solved an overheating issue involving the bearings on a dust extraction fan at an ore preparation plant, it led to significant annual cost savings thanks to the elimination of compressed air cooling. A comprehensive application review revealed that high bearing speed was causing seal lip burn-off and over-lubrication, contributing to elevated running temperatures. NSK therefore recommended its high-performance NSKHPS spherical roller bearings with SNN plummer blocks and labyrinth seals, along with proposals for correct lubrication intervals and quantities. The result? Annual savings of €88,955 as there is no longer any need to run the compressor for cooling purposes.

In another application, a recycling plant that was experiencing regular failures of mounted bearings on the conveyor of an optical sorting machine enjoyed major gains after switching to NSK SNN series plummer blocks with NSKHPS spherical roller bearings. Thanks to a reduction in replacement bearing costs, breakdowns and maintenance, the facility saved €51,174 per annum. In fact, the recycling plant went from 10 breakdowns a year, to none.

Elsewhere, when a UK company was experiencing constant bearing failures on an autoclave bogie wheel assembly, the customer sought guidance from NSK to resolve the issue. On average, the company was witnessing bearing failures on the 10 axles of the autoclave bogie wheel assembly every 2-3 weeks. In addition, the failures of the deep groove ball bearings were resulting in damage to the surrounding housings and axles, in turn promoting high labour and part replacement costs.

NSK performed a failed bearing analysis as part of its Added Value Programme, during which it was determined that the ingress of hard particulates and moisture, combined with excessive load, was the root cause of the failures. As a result of switching to NSKHPS spherical roller bearings, there was no longer any need for ongoing maintenance, substantially reducing collateral damage to the surrounding components. In total, the customer saved €138,382 in reduced bearing, maintenance and hardware costs.

Holistic approach

AIP is a holistic approach to delivering added value that helps customers embark on a critical path to realising improvements in equipment, productivity, people and financial performance.

In essence, AIP is a simple five-step cycle performed by NSK: evaluation – make site visits to gather data and understand the challenges; recommendation – create a solution and set out the anticipated savings; implementation – provide assistance with the installation and test the recommended solution and, if appropriate, refine it for improved operation; validation – monitor performance to ensure delivery of the anticipated results; and extension – collate data, share learning and potentially expand the service to other applications within the company.

Ultimately, armed with tools such as AIP and products like NSKHPS bearings, it becomes possible to add significant value and drive down TCO, particularly in challenging applications where the expectations are invariably demanding: to run harder, faster and longer. In addition, the ability to transcend their role of mere load-bearing components to become performance enhancers – mitigating maintenance and operating costs, improving throughput and profitability – is a real measure of NSKHPS differentiation.

Synthesis of technologies

NSKHPS bearings are a synthesis of NSK technologies that include tribology, innovative mechanical design and advanced manufacturing. The outcome is bearings engineered to outperform and outlast conventional iterations, meeting industry’s ever-increasing challenges with significant and proven advantages. As a point of note, aside from extended operating life and enhanced performance, NSK can also provide added-value solutions for companies looking to use bearing innovation for energy and CO2 reduction initiatives.

Added value is simple to define, namely an improvement or addition to a product that makes it more valuable to customers. Bearings, once seen as mere commodity items, are now firmly on the list of vital engineering components that can make a significant difference to bottom-line profitability through added value.

Charlie Korten is marcomms and press specialist at NSK

Key Points

- Companies are realising that bearings are not simply commodity items, but components with the potential to add real value

- OEMs and end users opt for NSKHPS series bearings when there is a need for extended service life in arduous conditions

- AIP is a holistic approach to delivering added value that helps customers embark on a path to realising improvements

- NSK Europe makes significant environmental progress

- Condition monitoring agreement

- Bearing failure reduced significantly

- High-load-capacity tapered roller bearings

- More counterfeit NSK merchandise uncovered

- New cutting facility to reduce lead times

- Reliable lubrication

- NSK trains production staff using VR technology

- Wave power – using NSK ball screws

- Machine downtime eliminated