|

Charlotte Stonestreet

Managing Editor |

| Home> | DRIVES & MOTORS | >Variable Speed Drives | >Greater speed & torque control |

Greater speed & torque control

15 October 2014

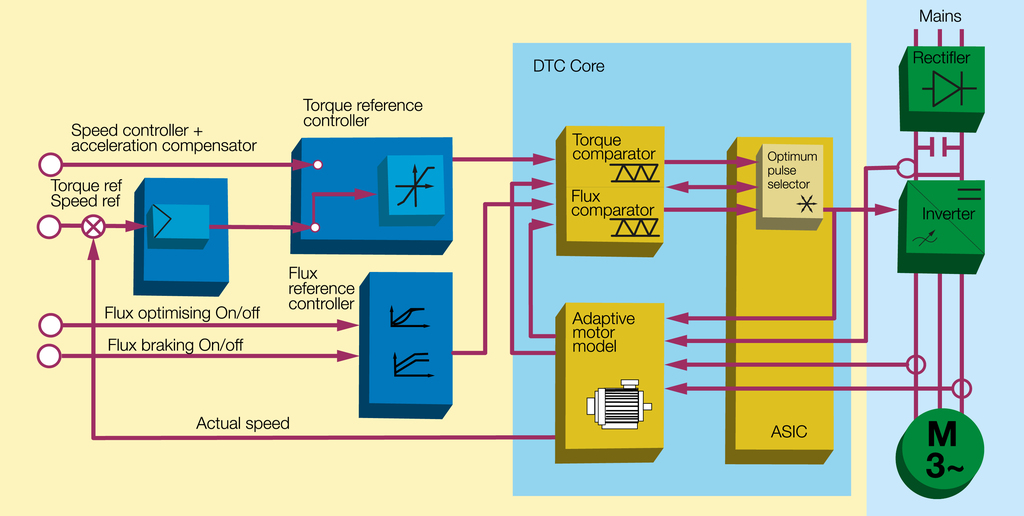

The motor control platform, direct torque control (DTC) – used extensively in ABB’s variable-speed VSDs since 1996 – has been improved to bring even higher accuracy in motor speed and torque control, as well as the ability to control more motor types.

The fourth generation DTC provides enhanced performance in open and closed loop and a higher switching frequency. Speed and torque control accuracy have been improved, for both dynamic and static values.

Support for high speed motors up to 500Hz (as standard) and absolute encoder and resolver support are provided, while other improvements include more choice of identification (ID) set-up runs. These include highly accurate standstill ID runs, allowing the drive to identify the motor from its performance characteristics without the need to uncouple the motor from the load.

- PUMPED UP PERFORMANCE

- SOFT STARTER OR VARIABLE SPEED DRIVE?

- Jeans With Less Energy

- Enhanced to Withstand Tough Environments

- Savings From Improved Torque Ratio & Efficiency

- Modular VSD

- ENERGY SAVING: AN OLD MESSAGE WITH NEW PROMISE

- Updated installation guide for power drive systems

- UK drives manufacturer seals global automation deal

- WEG motors & drives power high-efficiency air blowers