|

Charlotte Stonestreet

Managing Editor |

| Home> | POWER TRANSMISSION | >Gear Drives | >Top accuracy during milling operations |

| Home> | POWER TRANSMISSION | >Gearboxes | >Top accuracy during milling operations |

Editor's Pick

Top accuracy during milling operations

27 September 2013

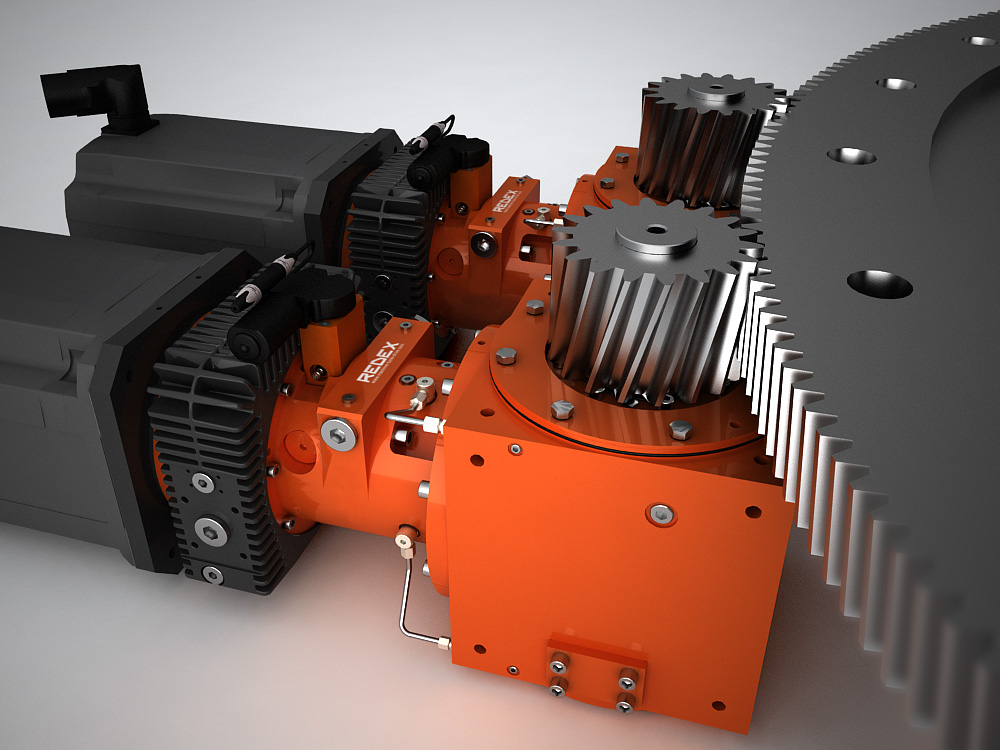

Redex has enhanced its solutions for turning tables on large vertical lathes. The latest MSR drive designs have been refined using the newest generation of drive and control systems from Siemens CNC or Fanuc.

The MSR drive is composed of two identical gearboxes (TwinDrive system), sharing the driving torque (50%-50%) during turning operations. With the help of the CNC system which manages the motor preload torque, the system is able to cancel 100% of backlash.

In addition, MSR exclusive features enable a very accurate positioning level, allowing the execution of additional functions on the C axis, without any additional mechanical devices. For instance, top accuracy is kept during milling operations with one motor driving and the other motor braking.

- Parvalux Gives Mechanical Sculpture Drive

- GEARBOX IS CHEAPER TO REPLACE THAN REPAIR

- PLANETARY/SPUR GEARBOXES

- PLANETARY GEARS WELL SUITED FOR RETROFIT

- AGEING WORM GEARS REPLACED BY PLANETARY GEARS IN SEWAGE PLANT

- REHFUSS BRINGS QUALITY AND VERSATILITY TO GEARBOX DESIGN AND SELECTION

- FLEXIBLE COUPLINGS

- GETTING THE BEST OUT OF GEARBOXES

- As Long As The Wind Blows

- RACK-AND-PINION REDESIGN CUTS GEAR SIZES