|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Systems | >Orchestrating a modular approach |

Orchestrating a modular approach

11 October 2024

The name Module Type Package tells you very little about what it is and nothing about its benefits. Ian Manning sheds some light on MTP solutions

IN TODAY'S marketplace product life cycles are getting shorter. Where previously production or process lines were built and remained unchanged for decades, a modern line has to be flexible. As demand grows production must grow with it. Conversely when demand slows and it becomes uneconomical to leave the production or process line with over capacity, the line needs to shrink and its components moved to either make new lines, or to expand lines where demand is growing.

Achieving this flexibility is normally expensive and time consuming, which reduces potential returns. Although modularity in production and process lines isnít new, every manufacturer of a module has a different control system and interface, requiring extensive rewriting of the control system and commissioning for every change in the line. This is where the MTP solution steps in.

MTP is a manufacturer-independent interface which describes the modules functions. The modules internal control system implements the functions in the same way that a manager delegates a task to a colleague. The higher level control system doesnít need to know how the module implements the function, just that it is being done.

Orchestrate instead of programming

While the conductor in an orchestra keeps everyone in time and directs the performance, he doesn't actually play any of the instruments.

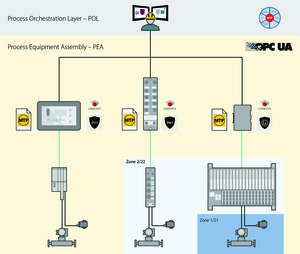

Instead of programming to control individual actuators in the modules, a new Process Orchestration Layer (POL) based upon SCADA, MES or IIoT sends commands to the services of the module. The status and process values of the services are received by the POL in order to continue the process control. As the commands are standardised across all manufacturers, a similar module from any manufacturer can be controlled without any changes to the POL.

This doesn't just benefit the end customer. Skid builders can use different equipment manufacturers, thereby shortening production times and alleviating component shortages.

Production lines can be built or expanded with any available modules, ensuring that production is matched to demand in the most cost-effective way.

Time to market can be reduced by up to 50%, engineering effort can be reduced by up to 70% and flexibility increased by 80%.

With its portfolio, Turck Banner can offer a wide variety of MTP solutions for end-to-end modularization in production. Using the globally proven, manufacturer-independent Codesys system platform allows the use of different fieldbus/Ethernet protocols in one automation system.

The Edge Controller generates the MTP file based on Codesys. It is then stored and installed in the Process Orchestration Layer (POL). The instructions are communicated via the industry standard OPC UA, which is supported by a large number of devices from different manufacturers. The MTP can be used to quickly integrate PEAs (Process Equipment Assembly) into modular plants. This provides the basic prerequisite for end-to-end modularisation in production, allowing rapid commissioning and enabling plug and produce.

The standardised interface also provides diagnostics and predictive maintenance. MTP defines services to configure, visualise, and operate smart Process Equipment Assemblies. (PEAs)

Ian Manning is marketing director at Turck Banner UK

- Shining a light on flexibility

- Sustainability germinates at Turck Banner

- Immune to magnetic fields

- Sustainability through supply chain management

- Get connected!

- Quick & powerful wireless monitoring

- Industrial connectivity - the past, present & future

- Visual factory comes into focus

- Cutting edge monitoring

- One system for all zones

- SWISSLOG SECURES MAJOR ORDER

- IMPROVED PERFORMANCE & RELIABILITY

- Engine Facility

- BULK AUTOMATION

- Integrated Packaging Solutions

- INTEGRATING ELECTRIC AND PNEUMATIC CONTROLS

- Rockwell Automation expands Midrange system portfolio

- Yokogawa joins Friends of the Supergrid

- Festo extends reach of VTUG and MPA-L valve terminals

- Siemens extends TIA Portal engineering framework