|

Charlotte Stonestreet

Managing Editor |

| Home> | POWER TRANSMISSION | >Bearings | >Sensor technology integrated into spindle bearings |

Sensor technology integrated into spindle bearings

22 January 2018

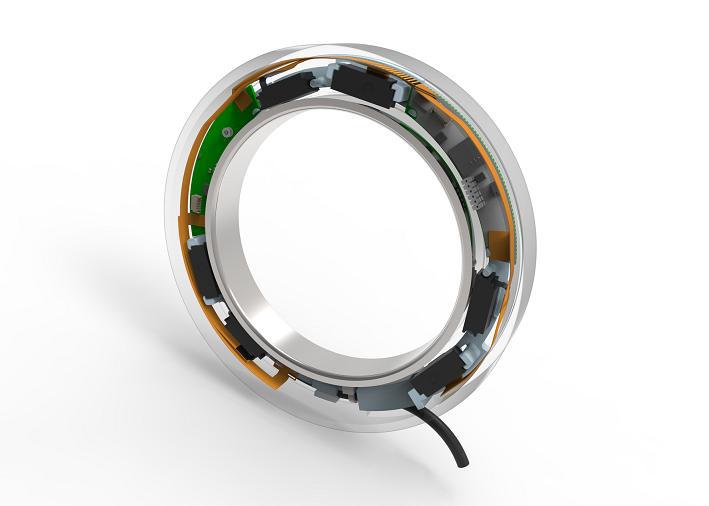

At EMO 2017, Schaeffler presented a revolutionary system for maximising the OEE (overall equipment efficiency) of machine tools – a newly developed range of sensors for main spindle monitoring that are integrated into the spindle bearings themselves.

This means machine manufacturers can now offer their customers a highly effective and easy-to-use device for increasing machine availability, productivity and quality. Using this system will reduce the frequency of spindle failures while simultaneously extending the operating life of the spindles.

The completely new sensor system, which has been developed specifically for this application, measures the displacement of the spindle shaft under load in high resolution and in five spatial directions – three translational and two rotary. This, combined with the matching expertise in rolling bearings, makes the kinematic conditions in the bearing and thus the operation-related parameters such as pressure, spin/roll ratio and cage pocket clearance, to be clearly calculated.

- Schaeffler & Siemens to cooperate on intelligent diagnostics for drive systems

- Automatic relubrication

- Closed loop engineering

- New generation of rolling bearing housings

- Optimum lubrication for linear guides results in longer machine operating times & reduced maintenance

- SBTi validates Schaeffler Group's emissions targets

- SCHAEFFLER RECEIVES GLOBAL QUALITY AWARD FROM NISSAN

- Linear profile rail system replacement

- Former ambassador Dr Peter Wittig joins Schaeffler to head Global Affairs unit

- Schaeffler becomes an e-F@ctory Alliance partner