|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Systems | >6-axis positioning |

6-axis positioning

09 June 2015

Used to determine properties of x-ray diffraction crystals prior to installation into x-ray sensitive diagnostics for fielding on laser plasma experiments, LG Motion, has recently delivered a 6-axis vacuum-compatible precision motion system to AWE Aldermaston.

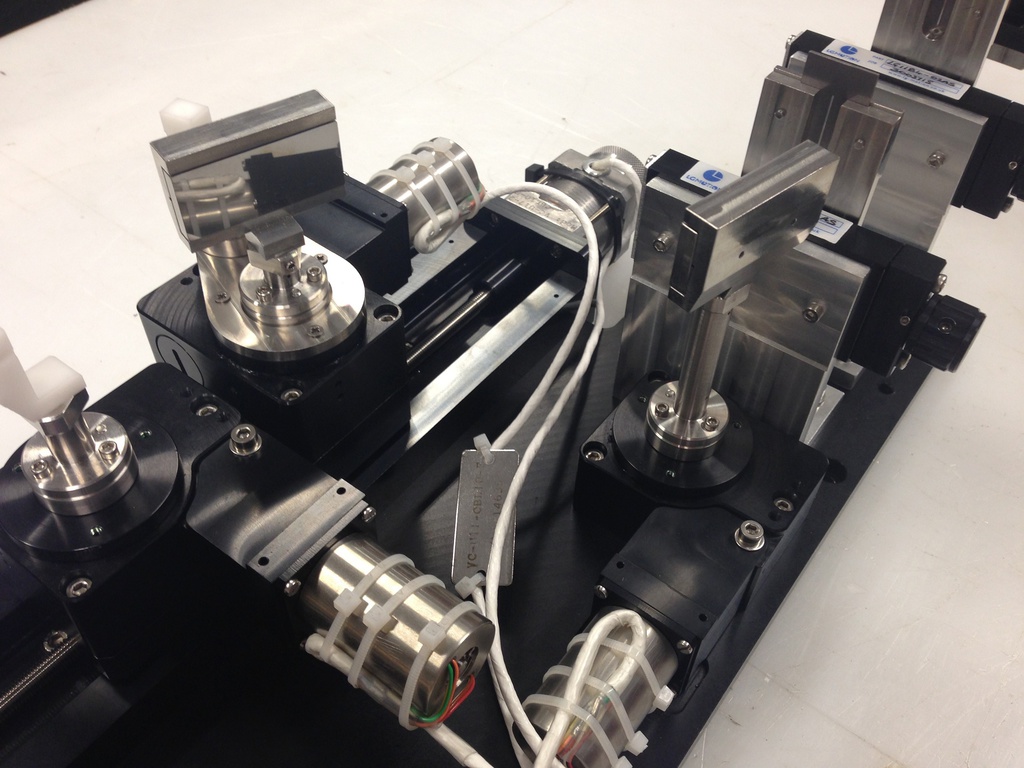

The PC controlled ‘Two Crystal Characterisation Positioning System’ includes three stepper motor driven rotary tables and a 350mm travel stepper driven linear axis that combine to support optical diffraction mounts and sensors, with two 35mm travel manually adjustable linear stages used to pre-position static optical equipment.

LG Motion’s pre-programmed user interface allows operator and supervisor level access to set-up and calibrate the optical system, and to load and run coded pre-defined characterisation routines that run across the PC and the motion controller, producing and storing characterisation data.

The complete system includes a control cabinet, housing the motion controller and stepper motor drives, with all positioning mechanics mounted on an aluminium baseplate. AWE integrated the mechanics into the vacuum chamber with connections through their vacuum bulkhead to the cabinet via 5 metre cables. The scope of supply included 10-6 vacuum preparation with special lubrication and holes as through-holes or bleeder cross holes to avoid any possibility of cavities forming under vacuum.

All motorised axes used vacuum compatible micro-stepping motors from motor specialist Empire Magnetics Inc., a distribution partner of LG Motion and regularly used and specified for hostile environment applications.

The rotary and linear stages were vacuum modified standard tables from LG Motion’s LG series – part of a wide range of standard linear, rotary and elevation stages that are available with stepper or servo motors to form complete multi-axis positioning solutions. The specification for the positioning mechanics called for <0.075mm for the linear stage and <0.1 degrees for the rotary tables whilst repeatability was <0.02mm and <0.05 degrees.

The assembly was fully tested and CE marked at Basingstoke then transferred to the customer where site acceptance testing was carried out with AWE and LG Motion engineers.- Miniature rotary stage

- Telescopic lifters

- Cobots - transforming the factory floor

- LG Motion appointed distributor for Arcus Technology

- Integrated evaluation kit

- The best things come in small packages

- Motion control solutions

- LG Motion becomes UK distributor for Baumeister & Schack

- Actuator & motion control

- Motion system extremes

- SWISSLOG SECURES MAJOR ORDER

- IMPROVED PERFORMANCE & RELIABILITY

- Engine Facility

- BULK AUTOMATION

- Integrated Packaging Solutions

- INTEGRATING ELECTRIC AND PNEUMATIC CONTROLS

- Rockwell Automation expands Midrange system portfolio

- Yokogawa joins Friends of the Supergrid

- Festo extends reach of VTUG and MPA-L valve terminals

- Siemens extends TIA Portal engineering framework