|

Charlotte Stonestreet

Managing Editor |

| Home> | MACHINE BUILDING & ENGINEERING | >3D Printing & Prototyping | >The multi-sector potential of 3D printing |

The multi-sector potential of 3D printing

14 June 2023

In the face of rising raw material costs, engineers and manufacturers must source viable ways to reduce material consumption for product development and production. One solution which is starting to play a crucial role in the future of manufacturing is 3D printing, explains Luke Smoothy

IT HAS been widely reported that additive manufacturing dramatically reduces the production of scrap waste – sometimes by as much as 90% compared to traditional manufacturing. In the case of multi-material 3D printing, like 3D printed electronics, there are less part counts while electrical and mechanical functionality is combined to give a more streamlined, efficient and sustainable production process.

For most components, extra material with conventional production can also be removed at the design stage, as 3D printing uses only the exact required amount of material to create a part or product. This not only makes 3D printing more cost efficient over the full lifecycle of the part but also helping to protect the environment by creating less waste when compared to other subtractive forms of fabrication, such as milling or laser cutting.

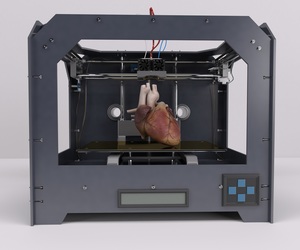

3D printing, as a single step manufacturing process, can manufacture parts within hours, helping to cut lead times and cost. Additive manufacturing also complements traditional manufacturing by providing new opportunities for small-batch production of complex parts, offering great design freedom with minimal or even no additional cost for increasing the complexity of a design. These potential gains and benefits make it an ideal tool for rapid prototyping across multiple sectors, and why the medical industry is just one case in point, which is now embracing the technology for the development of new devices.

A medical miracle?

Customisation, lower production costs, and quick turnarounds are said to be the factors that will drive growth within the medical 3D printing market from just over £1.6 billion in sales in 2022, to more than £3.2 billion in 2026 at a CAGR of 21%.

It is enabling solutions for a broad spectrum of needs ranging from PPE to medical devices and isolation wards, as well as being used to create custom prosthetics and implants to meet the individual needs of a patient, improving functionality and patient comfort.

There are wider-reaching benefits too. 3D-printed surgical guides can act as an aid to surgeons performing joint replacement, spinal, and other complex surgeries, leading to improved accuracy and precision during procedures, increased success rates, and reduced recovery times.

In particular, 3D printing’s capabilities in simplifying complex geometries will only accelerate its future use in the medical sector, for example through printed ‘smart materials’, with geometries that are nearly impossible to produce using other methods, enhancing current devices with new properties and improved performance. Some of the ‘smart’ devices currently being researched include prosthetic limbs with built-in sensitivity, self-expanding stents, self-healing joint replacements, and drug delivery devices that respond to infection.

Adapting design and size to reduce costs

While 3D printing can help to further reduce costs, Get It Made believes that by making some extra, simple adjustments with the design and size, manufacturers can minimise the overall cost of a part.

“Having solid designs with a lot of material can seriously eat into budget, so manufacturers can reduce the amount of material used just by hollowing out the middle of the design to create an outer shell,” explains founder and director Luke Smoothy. “Design optimisation is another way to lower costs. This is where additive manufacturing differs to traditional manufacturing processes like CNC machining, because adding extra holes to your component can reduce the part cost as opposed to increasing it, as less material is used which decreases production time.

He continues: “And don’t forget the size of the actual part – by shrinking it, this has a direct correlation to the bottom line. It’s not rocket science that a bigger part requires more material and therefore ramps up print time. Similarly, when it comes to manufacturing a design for proof of concept, opting to scale down the model size can also minimise cost and lead time. This speeds up the prototyping phase and is cheaper than a full-scale design.

“Another option is to have an internal lattice in place of solid features in your design. Lattices are ideal if you want to use less material without substantially compromising the part’s structural strength.”

Case study: the innovative 3D tech making waves

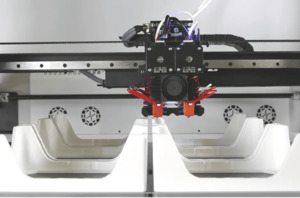

In 2020, Get It Made was asked by C-Monsta to manufacture via its 3D printing capabilities a working prototype to dry wet suits, fittingly named ‘The Wetsuit Hanger’.

As a keen surfer in Scotland, C-Monsta’s Founder and Director Mark Yeadon, the concept of a wetsuit hanger had been in his head for a while. While surfing during winter, the only time of year which saw significant waves, his wetsuit and accessories would often get neglected in the back of a van for days when removed, often a habit of surfers. When neoprene (the wetsuit material) isn’t properly dried, it smells, and can lead to the fabric and seams rotting, ultimately limiting the lifespan of the wetsuit.

Yeadon wanted to create a design solution which would not only dry surfing gear faster to prevent bad smells and rot but also extend its lifespan in order to reduce landfill waste, as neoprene isn’t recyclable. It was the first time he had taken a project from the prototype stage to being mass-manufactured on a large scale.

“Before the design of the product could be approved for mass production, our team of project managers undertook the process of curating a working prototype of the component, creating a convenient drying tool for those who are bold enough to brave cold waters.

Describing the process of creating a prototype for his company’s product, Yeadon said: "Although I love problem-solving, this was the first time I had worked on designing and manufacturing a product. I had gotten to a point where I had designed and proved the concept but could not find a way to manufacture it economically. I was given a grant to work with a designer at the Glasgow School of Art, where my idea was refined and modelled it for injection moulding. We ran out of time on the project before completing the design, and I couldn't afford to pay for the design to be completed, so I rolled up my sleeves, and worked out how to use Fusion 360 to finish the modelling process on my own. I then required a 3D printed model, which is where Get It Made stepped in.

“When the model arrived, I was amazed by the quality of the finish. The approach they have is very straightforward, proactive, pragmatic and professional. They helped me choose the best materials to simulate my final product, were quick to price with good communication, delivery was fast, and the product was exactly what we were after.”

Yeadon is already seeing the tangible benefits brought by 3D printing: “Using my prototype, my wetsuit lifespan lasted two winters instead of one, saving me £350 every two years. It is a low-tech solution with a relatively high impact on kit maintenance and lifespan. As well as being manufactured in the UK, the entirety of the wetsuit hanger is made from recycled plastics, as C-Monsta bids to leave behind the smallest carbon footprint possible, underlining the importance we place upon sustainability within the business.”

Luke Smoothy is founder and director of Get It Made

Key Points

- 3D printing, as a single step manufacturing process, can manufacture parts within hours, helping to cut lead times and cost

- It can be more cost efficient over the full lifecycle of the part and help protect the environment by creating less waste

- 3D printing’s capabilities in simplifying complex geometries will accelerate its future use in the medical sector

- The impact of digital technologies in manufacturing

- Connectivity & 5G in UK manufacturing

- Deployment of green hydrogen technology to be explored

- Nineteen Group acquires Broden Media Limited

- Innovations in Robotics Webinar to address cobot safety

- New method of manufacturing micromotor windings

- 10 million Euros of production improvements

- New business models & applications; the potential of Industry 4.0

- AI-driven waste robotics company secures funding

- Low-cost tactile sensor allows robots to feel