|

Charlotte Stonestreet

Managing Editor |

| Home> | MACHINE BUILDING & ENGINEERING | >3D Printing & Prototyping | >From model to manufacture |

From model to manufacture

21 July 2015

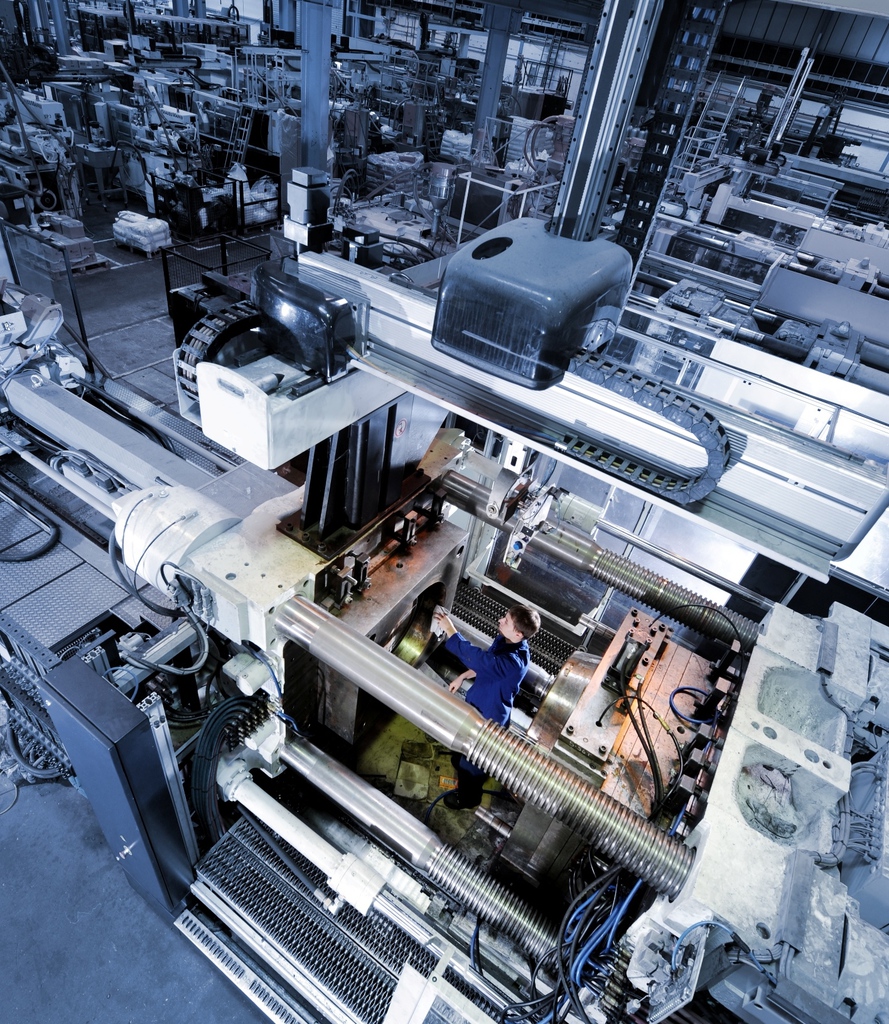

Whether you require injection mouldings or fully functional rapid prototypes, Rutland Plastics experts will be on hand to offer advice.

On the stand will be a selection of injection moulded parts in a variety of thermoplastics together with a selection of 3D printed prototype parts. Using the latest Stratasys Objet Connex 3D printer it is able to produce printed prototypes in a variety of materials as well as complex assemblies. Polymers that can be simulated include polypropylene, ABS, transparent and rubbers.

Rutland Plastics provides a full service including design, tooling, machining and assembly services in addition to rapid prototyping and injection moulding. The company has particular expertise in large and thick section mouldings up to 1.5m2 and 48kg in weight. It also offers gas assisted injection moulding. Stand G58